Basic knowledge of surface roughness (surf test)

JIS B 0601:2013 Geometric Product Specifications (GPS)-Surface Texture: Profile Curve Method-Terminology, Definitions and Surface Texture Parameters

JIS B 0634:2017 Product Geometric Characteristics Specifications (GPS)-Filtering-Linear Profile Filter: Gaussian Filter

JIS B 0633:2001 Geometric Product Specifications (GPS) - Surface Quality: Profile Curve Method - Methods and Procedures for Evaluating Surface Quality

JIS B 0651:2022 Product Geometric Characteristics Specifications (GPS)-Surface Properties: Profile Curve Method-Characteristics of Stylus-Type Surface Roughness Measuring Instruments

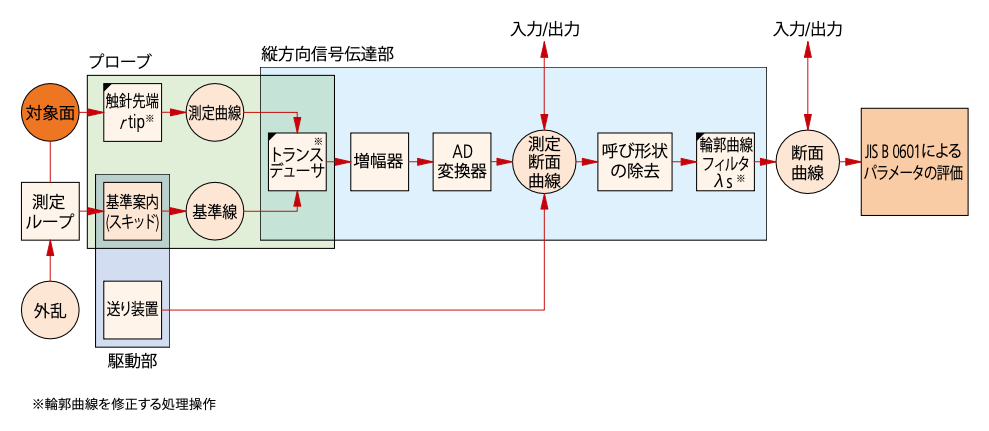

Elements of Contact Type Surface Roughness Measuring Instruments

ISO 3274: 1996 (JIS B 0651: 2001)

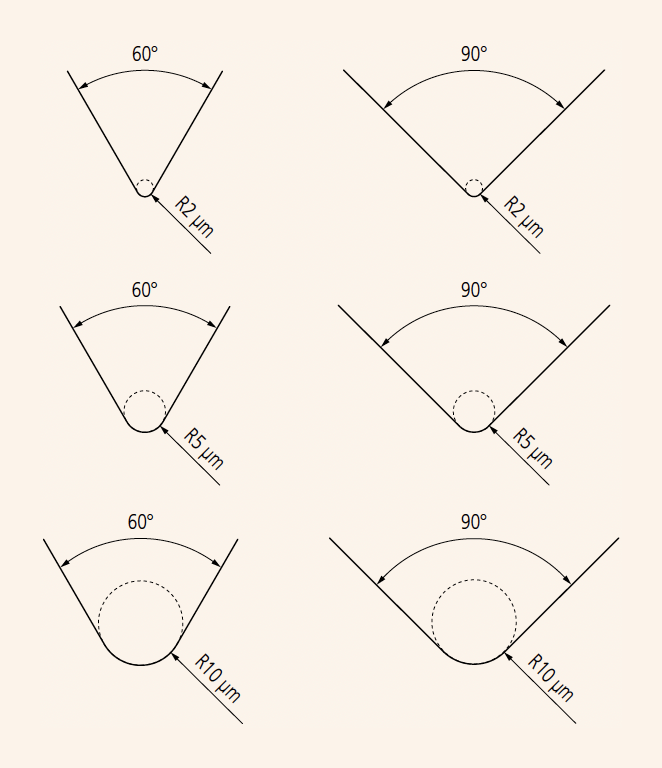

Stylus Shape

A typical shape for a stylus end is conical with a spherical tip.

Tip radius: rtip = 2 μm, 5 μm or 10 μm

Cone angle: 60°, 90°

In typical surface roughness testers, the taper angle of the stylus end is 60 ̊ unless otherwise specified.

Static Measuring Force (JISB0651)

Measuring force at the average position of the stylus: 0.75 mN

Measuring force change rate: 0 N/m

Standard characteristic value: Static measuring force at the average value of the stylus

| Nominal radius of curvature of stylus tip: μm | Static measuring force at the mean position of stylus: mN | Tolerance on static measuring force variations: mN/μm |

| 2 | 0.75 | 0.035 |

| Five | 0.75 (4.0) Note 1 | 0.2 |

| Ten |

Note 1: The maximum value of static measuring force at the average position of a stylus is to be 4.0 mN for a probe with a special structure including a replaceable stylus.

Relationship between Cutoff Value and Stylus Tip Radius

The following table lists the relationship between the roughness profile cutoff value lc, stylus tip radius r tip, and cutoff ratio lc/ls.

| λc (mm) |

λs (μm) |

λc/λs | Maximum rtip

(μm) |

Maximum sampling length (μm) |

| 0.08 | 2.5 | 30 | 2 | 0.5 |

| 0.25 | 2.5 | 100 | 2 | 0.5 |

| 0.8 | 2.5 | 300 | 2 Note 1 | 0.5 |

| 2.5 | 8 | 300 | 5 Note 2 | 1.5 |

| 8 | twenty five | 300 | 10 Note 2 | Five |

Note 1: For surfaces with Ra>0.5 μm or Rz>3 μm, using r tip=5 μm usually does not result in a significant difference in the measurement results.

Note 2: If a cutoff value ls is 2.5 μm or 8 μm, attenuation of the signal due to the mechanical filtering effect of a stylus with the recommended tip radius appears outside the roughness profile pass band. Therefore, a small error in stylus tip radius or shape does not affect parameter values calculated from measurements. If a specific cutoff ratio is required, the ratio must be defined.

Phase compensation filter characteristics

JIS B 0634:2017/ISO16610-21:2011

The filter for the contour curve is a phase compensation filter that has no phase lag (which causes the contour curve to distort depending on the wavelength).

The weighting function of the phase compensation filter is a normal (Gaussian) distribution with an amplitude transmission rate of 50% at the cutoff value.

Data Processing Flow

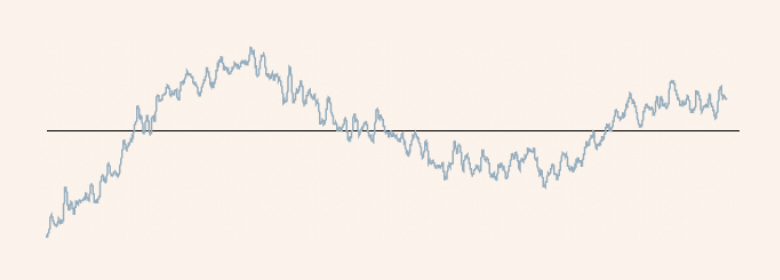

Surface Profiles

ISO 4287:1997 (JIS B 0601: 2013)

Primary Profile

Profile obtained from the measured profile by applying a low-pass filter with cutoff valueλs.

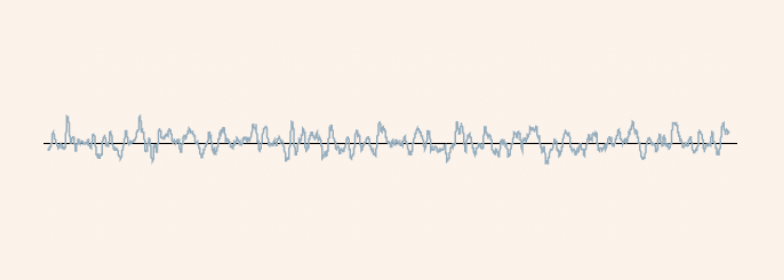

Roughness Profile

Profile obtained from the primary profile by suppressing the longer wavelength components using a high-pass filter of cutoff valueλc.

Waviness Profile

This is a profile obtained by applying profile filters with cutoff values λf and λc in sequence to the cross-sectional curve. The λf profile filter blocks long wavelength components, and the λc profile filter blocks short wavelength components.

Parameter definition

JIS B 0601:2013 (ISO 4287:1997, Amd.1:2009)

Amplitude Parameters (peak and valley)

Maximum peak height of the primary profile Pp

Maximum peak height of the roughness profile Rp

Maximum peak height of the waviness profile Wp

Largest profile peak height Zp within a sampling length

Maximum valley depth of the primary profile Pv

Maximum valley depth of the roughness profile Rv

Maximum valley depth of the waviness profile Wv

Largest profile valley depth Zv within a sampling length

Maximum height of the primary profile Pz

Maximum height of the roughness profile Rz

Maximum height of the waviness profile Wz

Sum of height of the largest profile peak height Zp and the largest pro- file valley depth Zv within a sampling length

* In the old JIS standard and ISO4287:1984, the symbol Rz is used to indicate the "ten-point average roughness." Caution is required because the difference in measurement values between the old and new standards is not necessarily so small that it can be ignored.

(It is necessary to check whether the drawing instructions are based on the old or new standard.)

Mean height of the primary profile elements Pc

Mean height of the roughness profile elements Rc

Mean height of the waviness profile elements Wc

Mean value of the profile element heights Zt within a sampling length

Total height of the primary profile Pt

Total height of the roughness profile Rt

Total height of the waviness profile Wt

Sum of the height of the largest profile peak height Zp and the largest profile valley depth Zv within the evaluation length

Amplitude Parameters (average of ordinates)

Arithmetical mean deviation of the primary profile Pa

Arithmetical mean deviation of the roughness profile Ra

Arithmetical mean deviation of the waviness profile Wa

Arithmetic mean of the absolute ordinate values Z(x) within a sampling length

Root mean square deviation of the primary profile Pq

Root mean square deviation of the roughness profile Rq

Root mean square deviation of the waviness profile Wq

Root mean square value of the ordinate values Z(x) within a sampling length

Skewness of the primary profile Psk

Skewness of the roughness profile Rsk

Skewness of the waviness profile Wsk

Quotient of the mean cube value of the ordinate values Z(x) and the cube of Pq, Rq, or Wq respectively, within a sampling length

The above formula is the definition of Rsk. Psk and Wsk are similar. Psk, Rsk and Wsk are the biases (measures of asymmetry of the probability density function in the height direction).

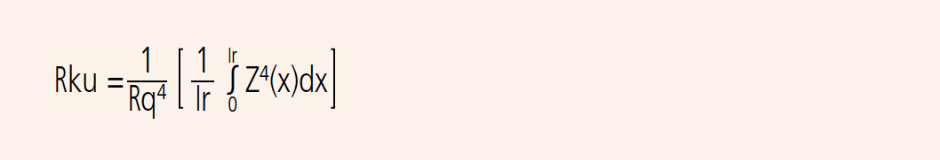

Kurtosis of the primary profile Pku

Kurtosis of the roughness profile Rku

Kurtosis of the waviness profile Wku

Quotient of the mean quartic value of the ordinate values Z(x) and the fourth power of Pq, Rq, or Wq respectively, within a sampling length

The above is the definition of Rku. Pku and Wku are similar. Pku, Rku and Wku are the quantities of sharpness of the probability density function of the ordinate values.

Hybrid Parameters

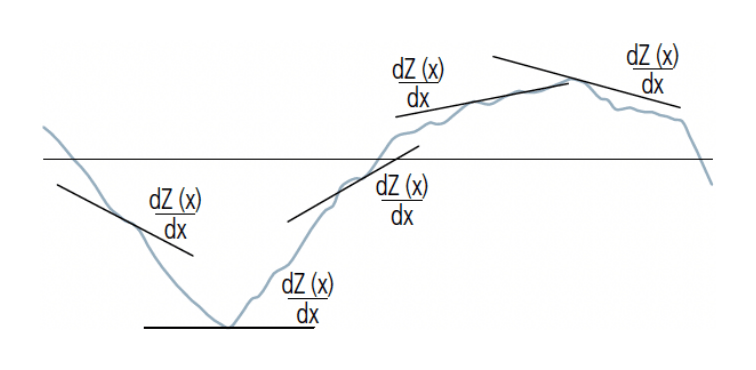

Root mean square slope of the primary profile P⊿q

Root mean square slope of the roughness profile R⊿q

Root mean square slope of the waviness profile W⊿q

Root mean square value of the ordinate slope dZ/dX within a sampling length

Spacing Parameters

Mean width of the primary profile elements PSm

Mean width of the roughness profile elements RSm

Mean width of the waviness profile elements WSm

Mean value of the profile element widths Xs within a sampling length

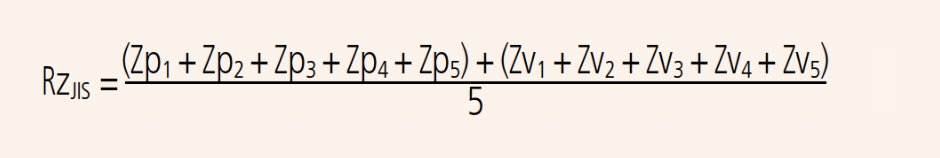

JIS Specific Parameters

Ten-point height of irregularities, RzJIS

Sum of the absolute mean height of the five highest profile peaks and the absolute mean depth of the five deepest profile valleys, measured from the mean line within the sampling length of a roughness profile. This profile is obtained from the primary profile using a phase-correct band-pass filter with cutoff values of lc and ls.

| Symbol | Used profile |

| RzJIS82 | Surface profile as measured |

| RzJIS94 | Roughness profile derived from the primary profile using a phase-correct high-pass filter |

Arithmetic mean deviation of the profile Ra75

Arithmetic mean of the absolute values of the profile deviations from the mean line within the sampling length of the roughness profile (75%). This profile is obtained from a measurement profile using an analog high-pass filter with an attenuation factor of 12db/octave and a cutoff value ofλc.

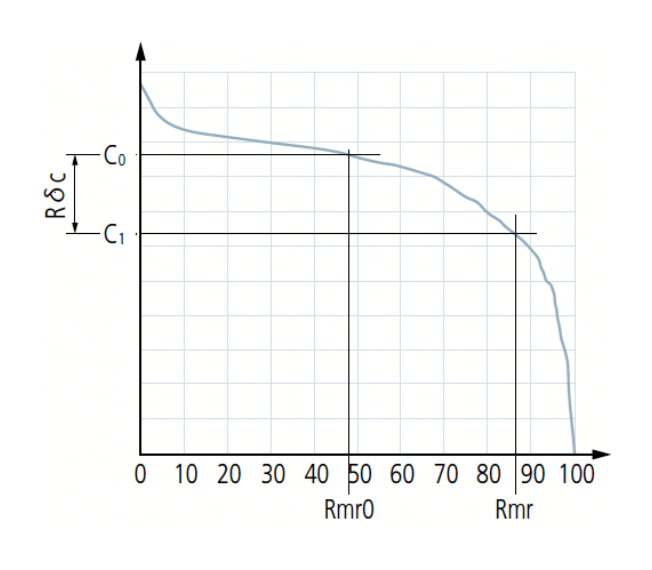

Material ratio curve of the profile (Abbott-Firestone curve)

Curve representing the material ratio of the profile as a function of sec- tion level c

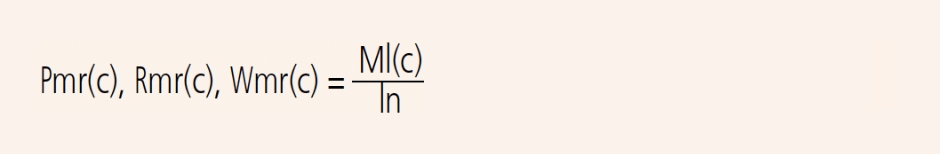

Material ratio of the primary profile Pmr (c)

Material ratio of the roughness profile Rmr(c)

Material ratio of the waviness profile Wmr (c)

Ratio of the material length of the profile elements Ml (c) at a given level c to the evaluation length

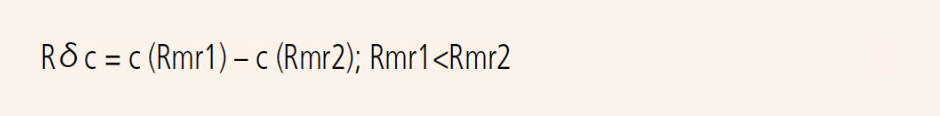

Section height difference of the primary profile Pδc

Section height difference of the roughness profile Rδc

Section height difference of the waviness profile Wδc

Vertical distance between two section levels of a given material ratio

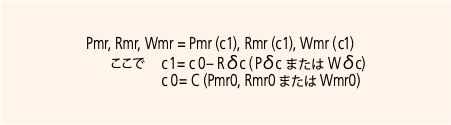

Relative material ratio of the primary profile Pmr

Relative material ratio of the roughness profile Rmr

Relative material ratio of the waviness profile Wmr

Material ratio determined at a profile section level Rδc, related to the reference section level c0

Probability density function (amplitude distribution curve)

Probability density function of height Z(x) obtained within the range of evaluation length

Roughness sampling length for non-periodic profiles

ISO 4288: 1996 (JIS B 0633: 2001)

Table 1. Sampling length of non-periodic profile roughness parameters Ra, Rq, Rsk, Rku, R⊿q and parameters related to the load curve and probability density function

| Ra (μm) | Sampling length lr (mm) | Evaluation length ln (mm) |

| (0.006)<Ra≦0.02 0.02<Ra≦0.1 0.1<Ra≦2 2<Ra≦10 10<Ra≦80 |

0.08 0.25 0.8 2.5 8 |

0.4 1.25 4 12.5 40 |

Table 2: Sampling lengths for aperiodic profile roughness parameters (Rz, Rv, Rp, Rc, Rt)

| Rz, Rz1max. (μm) | Sampling length lr (mm) | Evaluation length ln (mm) |

| (0.025)<Rz, Rz1max.≦0.1 0.1<Rz, Rz1max.≦0.5 0.5<Rz, Rz1max.≦10 10<Rz, Rz1max.≦50 50<Rz, Rz1max.≦200 |

0.08 0.25 0.8 2.5 8 |

0.4 1.25 4 12.5 40 |

1) Rz is used when measuring Rz, Rv, Rp, Rc, and Rt.

2) Rz1max is used only when measuring Rz1max, Rv1max, Rp1max, and Rc1max.

Table 3: Sampling lengths for measurement of periodic roughness profile roughness parameters and periodic or ape- riodic profile parameter Rsm

| Rsm (mm) | Sampling length lr (mm) | Evaluation length ln (mm) |

| 0.013<Rsm≦0.04 0.04<Rsm≦0.13 0.13<Rsm≦0.4 0.4<Rsm≦1.3 1.3<Rsm≦4 |

0.08 0.25 0.8 2.5 8 |

0.4 1.25 4 12.5 40 |

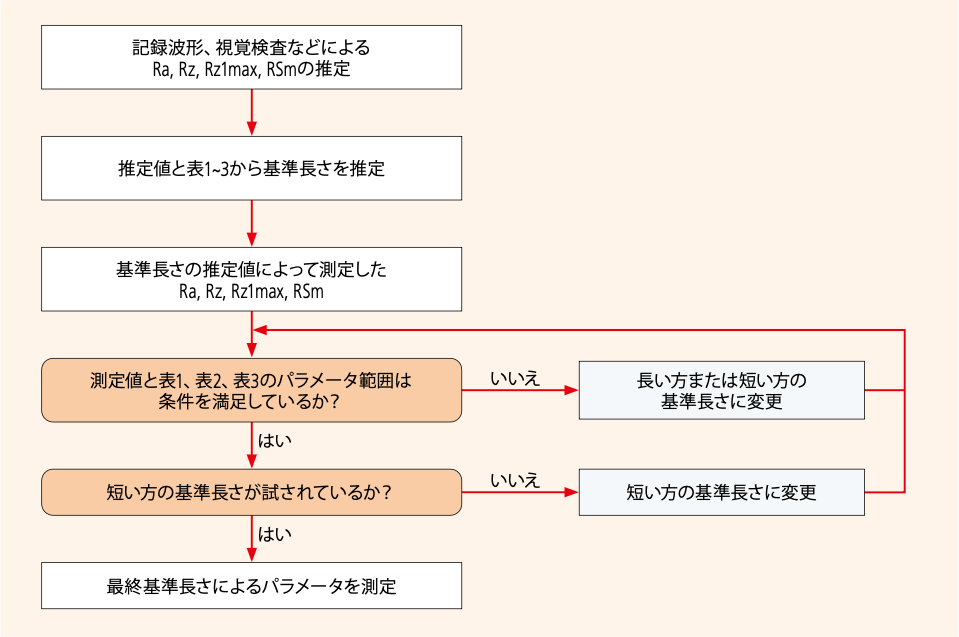

Procedure for determining a sampling length if it is not specified

Fig.1 Procedure for determining the sampling length if it is not specified

Fig.2 Procedure for determining the sampling length of a periodic profile if it is not specified.