Basic technology and equipment

We refine our advanced key technologies to create solutions that meet the needs of the times.

Based on the policy of ``having key technologies in-house,'' Mitutoyo develops and owns a wide range of advanced technologies in-house, including measurement technology, software, optics, mechanics, and electronics, as well as new technologies and technologies that meet the needs of the times. We work day and night on research and development of products and solutions.

measurement technology

Techniques for obtaining accurate and reliable measurement results

For accurate measurements, measuring instruments and measurement systems must be traceable with uncertainty. In addition, the methods and procedures for correct calibration, the standard for the measuring equipment, and the correction method for correct measurement are also important. These technologies provide accurate and reliable measurements.

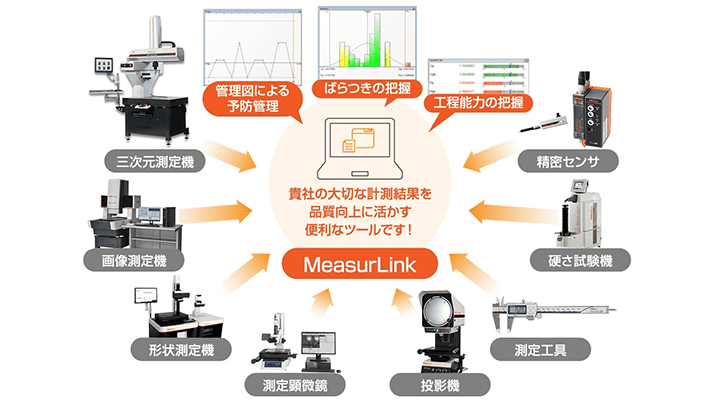

software technology

Providing user value by acquiring and analyzing measurement data

Even data obtained from properly calibrated measurement systems is affected by noise. Furthermore, measurements only provide partial information about the object. In this situation, we make it possible to find and provide truly valuable information by making full use of various technologies.

optical technology

In-house technology that supports non-contact measurement by “seeing and measuring”

Microscopes and non-contact products derived from optical design. We perform design and analysis using advanced optical simulations, predict the actual appearance, and realize lens processing that ensures stable "design quality" using in-house technology. We continue to focus on in-house manufacturing, including lens polishing, vapor deposition, adhesion, and assembly, and continue to pursue performance improvements.

Machinery/processing/assembly technology

Small digital caliper automatic inspection line

This is an in-house automatic inspection line that has developed a mechanism that faithfully reproduces traditional manual inspection, and can perform highly accurate and stable inspections. All inspection results are stored on a server, inspection sheets are automatically issued, and all serial numbers are managed to ensure traceability.

electronic technology

Custom IC development that supports Mitutoyo measurement business

In our electronics research and development, our global expert engineers utilize cutting-edge design verification tools and evaluation equipment to create custom IC development as our in-house technology. We create highly reliable measurement equipment by creating innovative custom ICs.

Control technology

Control technology that supports high speed and high precision

In order to achieve high speed and high accuracy in precision measurement, our proprietary vibration suppression control and accuracy compensation technologies are utilized.

The control device of the CMM uses a digital servo system, which makes it easy to install various vibration control algorithms. In addition, the spatial accuracy compensation and temperature compensation technologies installed in the control loop are essential technologies for guaranteeing accuracy.

sensing technology

Speeding up using light and moving measurement sensors in-line

In production sites where IoT is being introduced, there is a need to acquire measurement data and perform full inspections at each process, and high-precision non-contact sensors can quickly check design values and detect defective areas. In addition, to meet the demand for in-line and on-multi-task machines, measurements, we are creating products with excellent environmental resistance and durability, and working on the development of new sensing technologies.

universal design

Aiming for a design that is easy to use for everyone

Based on the basic concept of a design that is easy to use and attractive for everyone from the beginning regardless of differences in culture, language, nationality, age, gender, etc., or regardless of disabilities, Mitutoyo will continue to put itself in the user's shoes. We will continue to provide products and services that can be used safely and with confidence.

Equipment introduction

We will introduce our equipment, including the optical frequency comb device developed in-house that has world-class precision and controls Mitutoyo's length standards.

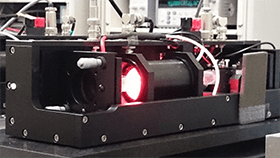

PICKUPDeveloped in-house “optical frequency comb device” with world-class length standard

Mitutoyo has developed and developed its own optical frequency comb device that can measure with ultra-high precision, even if the distance is the same as the distance from the Earth to the Moon (approximately 380,000 km), the error is only about the thickness of a hair. This device, which controls Mitutoyo's length standards, supports the foundation of Mitutoyo's measurement technology.

Appearance of optical frequency comb device

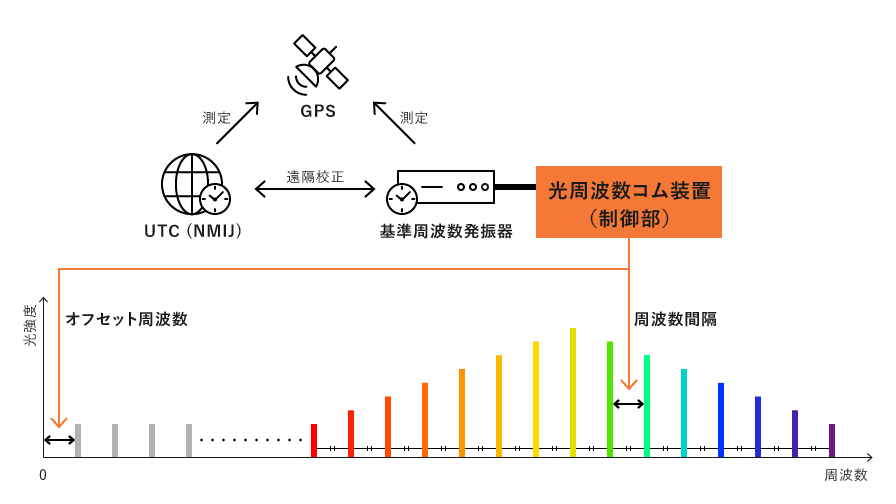

What is an optical frequency comb device?

One meter is defined as the distance that light travels in a vacuum in 1/299 792 458 seconds. The optical frequency comb device is an ``optical frequency measuring stick'' that can generate accurate optical frequencies based on a reference frequency oscillator that is traceable to national time standards.

Mitutoyo's optical frequency comb device achieves the world's top level calibration measurement capability of 1.1 We ensure traceability by undergoing remote calibration at approximately 960-second cycles via GPS, and we also maintain two optical frequency comb devices in-house and perform periodic mutual comparison evaluations to ensure the best performance. is maintained.