Information on special orders and customized products

To meet the diverse needs of our customers

Mitutoyo has a track record of responding to a wide variety of special orders and customized products in response to customer requests. We respond to the diverse needs of our customers, including special size products suited to improving business efficiency and customizations suited to new applications.

Features

-

Extensive manufacturing experience as a comprehensive manufacturer of precision measuring instruments. With over 80 years of experience in the precision measurement field and over 5,500 types of products, Mitutoyo responds to the diverse needs of our customers by leveraging our extensive manufacturing experience as a comprehensive manufacturer of precision measurement instruments.

-

We accept estimates for everything from the production of one item to the mass production of multiple items.

* Some products are not available as special orders or customized products.

-

For common custom-made items, the production period may be shortened. If it is a custom-made product that has been produced in the past, we may be able to deliver it in a short time by utilizing in-house manuals that speed up the finalization of specifications.

Example 1: Optical adapter for machine vision lenses

The TAGLENS system, which can significantly expand the depth of focus, can now be used with machine vision lenses.

TAGLENS and camera lens combined with an optical adapter

Features of this case study

- High focal extension effect allows for longer scan range

- Since it can be mounted on a small machine vision lens, the entire system can be made smaller, resulting in cost benefits.

- Ensuring a wide field of view

TAGLENS makes it possible to keep everything in focus up to 1.5m away (the image on the right is an enlarged version of the image)

We received a request from a customer to use TAGLENS, which can greatly expand the depth of focus, with machine vision lenses, so we developed a corresponding optical adapter. Conventionally, to observe objects that are high or far away, a robot was moved up and down, but by using the TAGLENS system, which can greatly expand the depth of focus, it has become possible to greatly simplify peripheral equipment.

Related products

Example 2: Large caliper with a maximum measuring range of 3m

With a maximum measurement range of 3,000 mm, it is possible to measure the dimensions of parts such as vehicles, large machinery, and large bearings, as well as after assembly.

Overall view of lightweight carbon caliper with a maximum measuring range of 3m

Features of this case study

- Customization was implemented to limit the measurement range to 2,000 to 3,000 mm, while leaving the range from 0 to 2,000 mm without a scale.

- The origin is set using a 2,000 mm reference rod, and direct reading is possible by using the preset function.

- Also supports waterproof function with protection rating IP66

With the standard product, the measurement length that the sensor can handle is limited to 2,000 mm, but the customer requested a maximum measurement range of 3,000 mm. Since the customer's application was for large workpieces, we customized the product to have a no-scale specification for 0 to 2,000 mm and limit the measurement range to 2,000 to 3,000 mm (measurement length 1,000 mm), thereby achieving a maximum measurement range of 3,000 mm. Large workpieces can now be measured stably.

Related products

Example 3: Special micrometer for measuring bolt head thickness

The screw part can be placed on the V-shaped anvil.

Easy to measure the thickness of the bolt head

A micrometer with a customized V-shaped anvil (The actual frame color may differ from the image)

Features of this case study

- Customize the anvil part of the micrometer to a V shape

- The threaded part of the bolt is placed on the V, and the head is clamped and measured, allowing the thickness of the bolt head to be measured quickly.

In response to customer requests, we have implemented customizations to micrometers to make it easier to measure whether the thickness of a bolt head is in line with the specified dimensions. With conventional micrometers, it was difficult to measure the thickness of a bolt head simply and stably, but this problem was solved by making the anvil V-shaped, placing the screw part of the bolt on the V, and allowing the bolt head to be clamped for measurement. The V-shape design allows for quick and stable measurements.

Related products

Case 4: Custom-made gauge blocks and applications

We can manufacture to order according to your specified nominal dimensions and special shapes.

Features of this case study

- We can custom-make to your specified nominal dimensions, such as frequently used sizes or small sizes that cannot be set with ringing.

- Please contact us for special shapes that cannot be achieved by machining from standard gauge blocks, as well as hole processing and engraving.

- Materials available are steel, ceramics, and low expansion ceramics

- We can also manufacture storage boxes with your specified set configuration.

Mitutoyo can manufacture a variety of custom gauge blocks to meet customer needs. As a comprehensive manufacturer of precision measuring instruments, we guarantee the accuracy of our products so that our customers can use them with peace of mind, and as a JCSS-certified business, we can establish traceability that leads to national standards.

Regarding the size, shape, and other conditions that can be produced

Please check below for the sizes, shapes, and other conditions that can be produced.

Other Cases

We also accept a wide range of other special orders and customized products. Please feel free to contact us for more information.

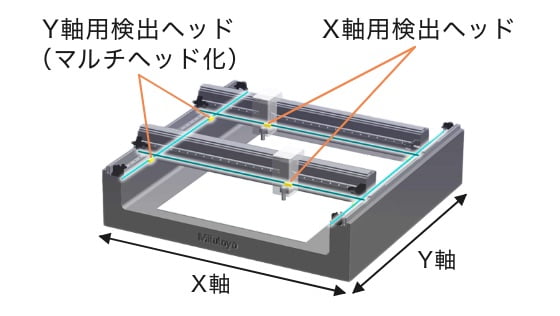

Sensor/device built-in unit

Linear scale ST700 multi-head type

It is possible to change to a multi-head system in which multiple detection heads are placed on a single axis scale.

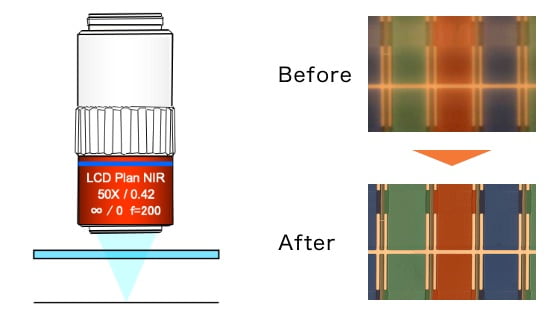

Glass thickness correction lens for objective lenses

We can design each product to order by specifying the glass material, thickness, and refractive index.

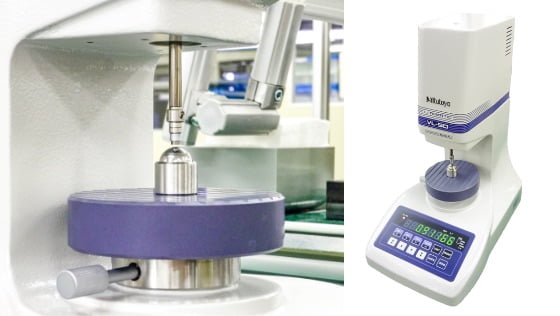

Litematic for contact lens thickness measurement

The stand, probe, and measuring force can be changed to suit the object being measured.

Measuring equipment

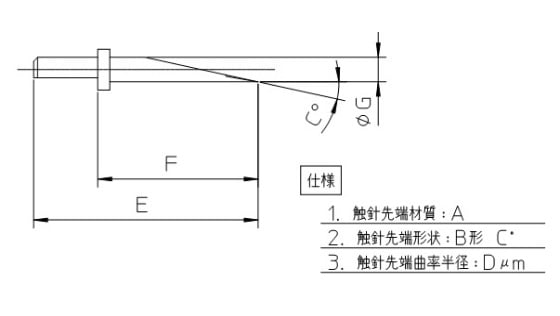

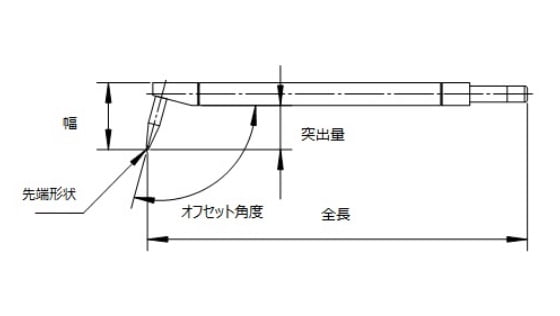

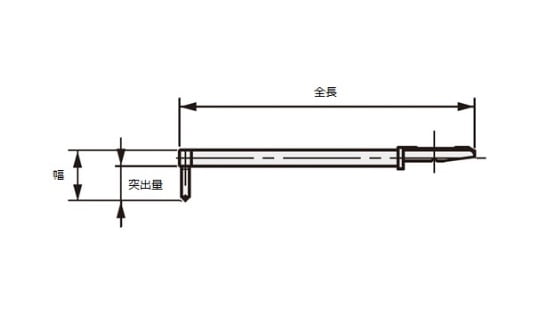

Special stylus for Form measurement

Special stylus can be ordered to measure a wide range of geometries.

* Please contact us separately for skid-equipped detectors.

Measuring tool

Special inside measuring device

By arranging the shell contact point and the sliding mechanism in the same straight line, we have achieved precise measurement in a compact size that does not take up much space.

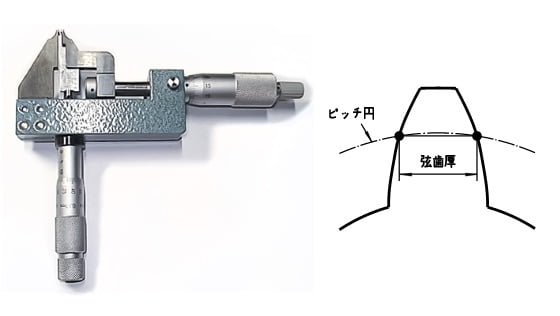

Gear Tooth Micrometer

This micrometer can measure the chordal tooth thickness of gears.

* Image and actual frame color may vary.

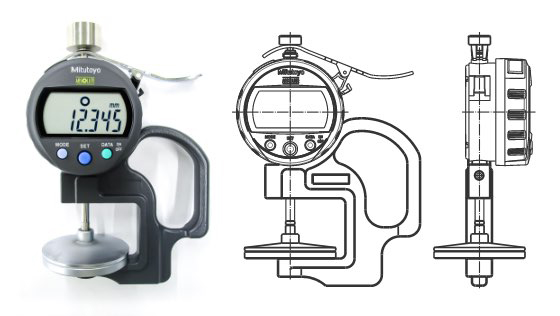

Special digital thickness gauge

The gauge head and anvil are φ50mm and are special types with weights. The measurement pressure is constant, making it suitable for measuring the thickness of films, etc.